Carbonation tester is a critical analytical instrument used to measure the carbonation level, CO₂ retention, and gas volume of carbonated beverages within sealed containers. For beverage manufacturers, packaging suppliers, and quality inspection agencies, accurate carbonation control directly affects taste, mouthfeel, shelf life, and brand consistency.

Cell Instruments Co., Ltd. designs and manufactures advanced carbonation testers to support precise, repeatable, and standards-compliant carbonation evaluation across PET bottles, glass bottles, cans, and customized packaging formats. By combining automation, high-accuracy sensing, and standardized test logic, our systems help users reduce human error while improving data reliability and customer confidence.

Gas Volume Test According to ASTM F1115

The gas volume test defined in ASTM F1115 provides a standardized approach for determining carbon dioxide loss and carbonation retention in beverage containers. This test method evaluates how well a package maintains its initial carbonation level over time under controlled conditions.

ASTM F1115 outlines two complementary procedures:

- Procedure A focuses on package development and shelf-life research. It relies on sensitive pressure and temperature measurement within a closed system and requires laboratory-level analytical expertise. This approach helps engineers evaluate structural performance, closure integrity, and long-term CO₂ retention characteristics of new container designs.

- Procedure B serves as a practical quality control method for beverage filling operations. It emphasizes operational simplicity while maintaining reliable accuracy. Automated or manual carbonation testers measure internal pressure and temperature after controlled agitation, then calculate carbonation levels using established carbonation tables. Because of its efficiency and repeatability, Procedure B is widely adopted in production environments.

A modern carbonation tester designed around ASTM F1115 allows users to calculate carbonation loss, carbonation transfer rate, and expected shelf life by tracking CO₂ retention over time. These results directly support packaging optimization and process control.

How the Carbonation Tester Works

A carbonation tester measures carbonation by establishing equilibrium between dissolved CO₂, internal pressure, and temperature inside a sealed container. The typical workflow includes:

- Automatic cap piercing to access internal pressure without uncontrolled gas loss

- Pressure stabilization to eliminate transient effects

- Controlled agitation to ensure uniform CO₂ distribution

- Simultaneous pressure and temperature measurement

- Instant gas volume calculation using embedded carbonation tables

This process ensures that each test reflects the true carbonation condition of the beverage, rather than operator technique or environmental variability.

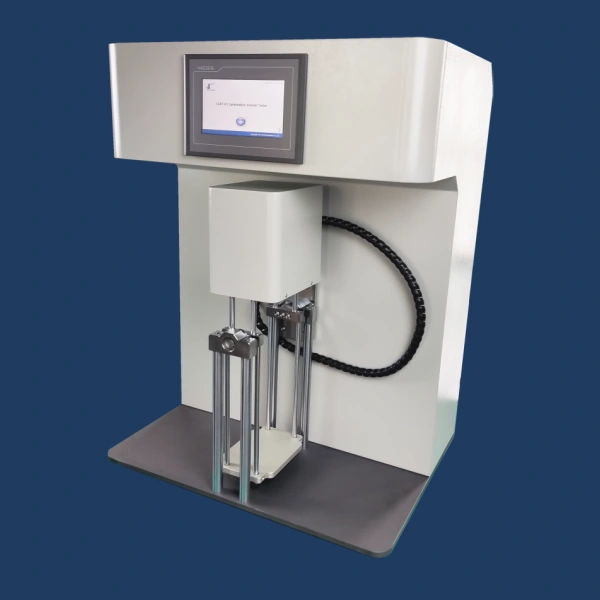

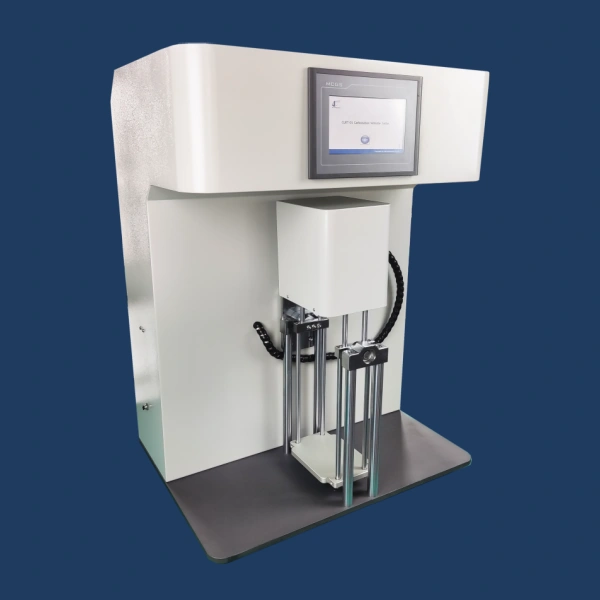

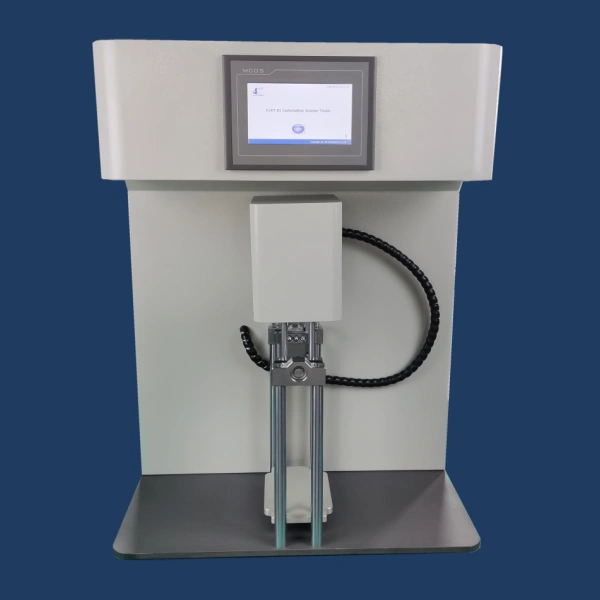

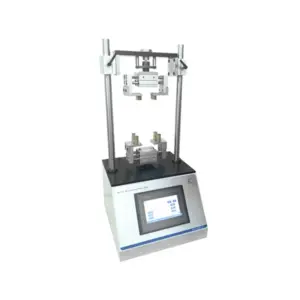

Automated Carbonation Testing with CLRT-01

The CLRT-01 Carbonation Tester from Cell Instruments enhances ASTM F1115-based testing through a fully automated, error-resistant workflow. The system integrates mechanical control, digital sensing, and intelligent calculation into one compact platform.

Key automation advantages include:

- Precision-controlled cap piercing with stable penetration speed

- Servo-driven agitation for consistent CO₂ equilibrium

- Real-time pressure and temperature capture using high-resolution sensors

- Instant CO₂ volume display, eliminating manual lookup and calculation

This design significantly reduces testing time while improving repeatability, making the carbonation tester suitable for both laboratory analysis and production-line quality control.

Why Accurate Carbonation Testing Matters

Carbonation loss directly influences beverage quality. Even a small deviation from the target CO₂ level can alter taste perception and reduce consumer acceptance. Reliable carbonation testing enables manufacturers to:

- Maintain consistent product flavor and mouthfeel

- Verify closure and package integrity

- Predict shelf life based on carbonation retention trends

- Meet internal quality standards and external regulatory requirements

By implementing a high-precision carbonation tester, quality control teams gain actionable data that supports both daily production decisions and long-term packaging development.