Bottle wall thickness gauge plays a critical role in packaging quality control, especially for manufacturers and testing laboratories involved in PET, glass, and pharmaceutical containers. Bottle wall thickness directly affects mechanical strength, barrier performance, weight consistency, and safety compliance. Even minor deviations can lead to deformation, leakage, or breakage during filling, transportation, or end use.

Bottle Thickness Measurement

PET Bottle Thickness and Glass Bottle Thickness Gauge

Understanding Bottle Thickness Distribution

Bottle thickness refers not only to an average wall value but also to its distribution across the bottle body, shoulder, and bottom. Uneven thickness often indicates problems during molding or forming. For PET bottle thickness, stretching ratios during blow molding strongly influence final wall distribution. For glass bottle thickness, forming temperature and mold condition play a decisive role.

A glass bottle thickness gauge and PET-compatible system must access curved and patterned surfaces without damaging the sample. Modern gauges achieve this by combining a stable test stand with a high-precision digital thickness probe.

Why PET Bottle Thickness Requires Precise Control

PET bottles demand strict thickness control to balance lightweight design and structural integrity. Excessive thickness increases material cost, while insufficient thickness reduces top load strength and impact resistance. Using a reliable bottle wall thickness gauge enables manufacturers to verify lightweighting results without compromising performance.

Working Principle of a Bottle Wall Thickness Gauge

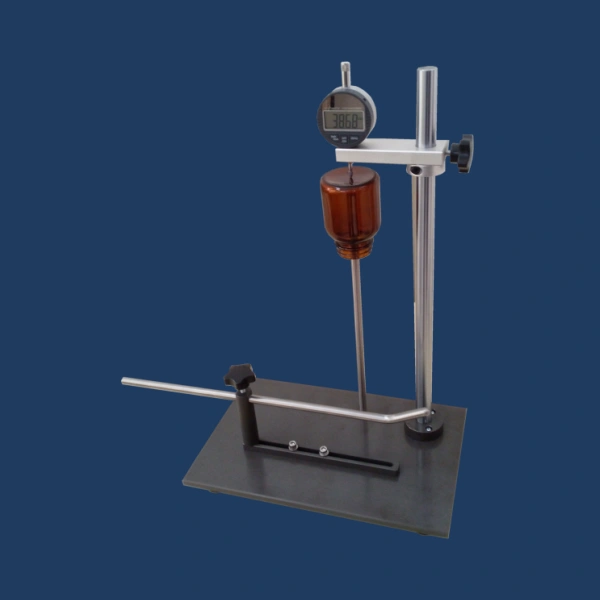

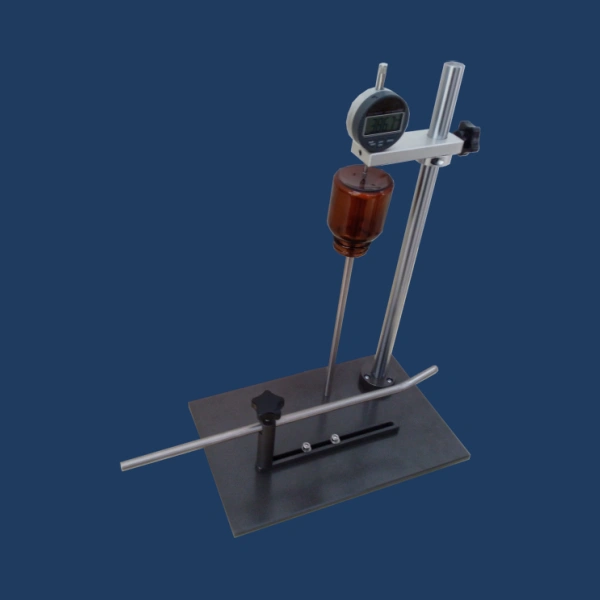

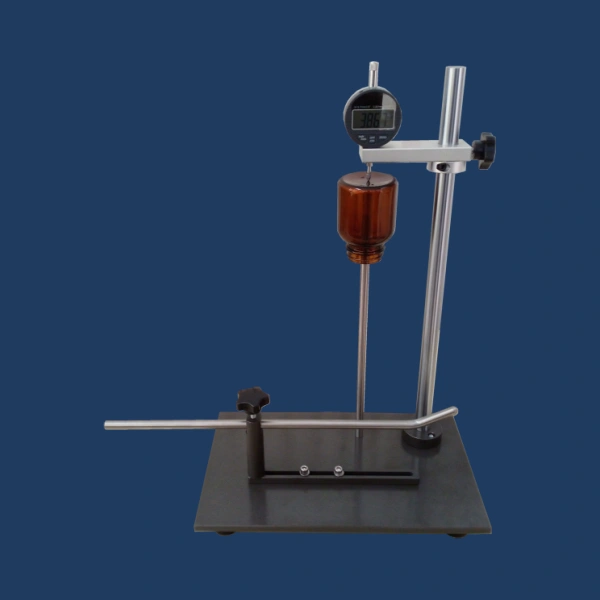

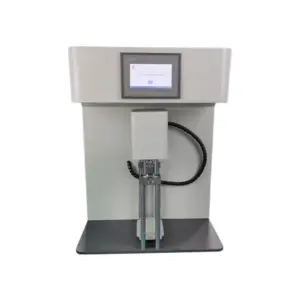

A bottle wall thickness gauge typically consists of:

- A stable vertical test stand

- A high-resolution digital thickness gauge

- A fine measuring probe designed for curved surfaces

During testing, the bottle is positioned on the stand, and the probe contacts the wall or bottom at a defined location. The gauge directly displays thickness values, allowing rapid comparison between different measurement points. Operators can complete a full bottle thickness profile efficiently, even on containers with complex geometries.

Advantages of Using a Professional Bottle Wall Thickness Gauge

Using a dedicated bottle wall thickness gauge provides measurable benefits:

- Improved production consistency by identifying thickness variation early

- Enhanced safety and compliance for food, beverage, and pharmaceutical packaging

- Reduced material waste through optimized thickness control

- Higher customer confidence supported by quantitative test data

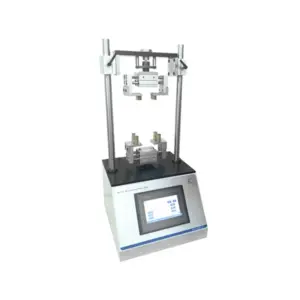

Cell Instruments designs its systems to ensure repeatability, durability, and ease of operation, even in high-frequency quality inspection environments.