The bottle perpendicularity tester evaluates how much the container’s central axis deviates from a theoretical vertical line. ISO 9008 provides a standardized and widely accepted framework for this evaluation, particularly for glass bottles.

According to ISO 9008, verticality reflects the horizontal deviation of the bottle’s center line, measured from the base center to the finish center. This definition accounts not only for overall tilt, but also for combined geometric effects such as base ovality, finish offset, or neck deformation. A bottle perpendicularity tester designed in line with ISO 9008 ensures that results remain comparable, traceable, and reliable across laboratories and production sites.

Why Bottle Verticality Matters in Quality Control

Bottle verticality plays a critical role in both production efficiency and end-use performance:

- High-speed filling lines require bottles to remain upright to prevent jamming or uneven filling.

- Capping and sealing processes rely on accurate alignment between the bottle finish and closure.

- Labeling and inspection systems depend on consistent bottle geometry.

- Stacking and transportation stability improves when bottles meet verticality tolerance.

A bottle perpendicularity tester allows manufacturers to control these risks through objective measurement rather than visual judgment.

Principle of Measurement Based on ISO 9008

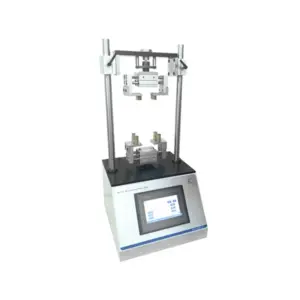

A bottle perpendicularity tester operates by holding the bottle base on a horizontal reference plane and measuring the deviation of the finish during rotation. For round bottles, the tester supports the sample using a V-block or a self-centering chuck. Non-round bottles remain centered on a dedicated rotating fixture.

During the bottle verticality test, the bottle rotates through 360°. The measuring probe records the maximum and minimum radial distances of the finish relative to a fixed reference point. The vertical deviation equals half the difference between these two values. This approach reflects the true vertical axis deviation, as defined in ISO 9008, rather than a single-point reading.

Key Advantages of Using a Bottle Perpendicularity Tester

A professionally designed bottle perpendicularity tester delivers several practical benefits:

- High repeatability through stable and controlled rotation

- Objective and quantitative results, reducing operator bias

- Compatibility with ISO 9008, supporting audits and compliance

- Early detection of forming or molding issues

- Improved customer confidence in packaging quality

Cell Instruments focuses on transforming the ISO methodology into an efficient, user-friendly testing process, suitable for both laboratory and production environments.

Application of Bottle Perpendicularity Tester in Different Industries

Bottle perpendicularity tester systems serve a wide range of industries:

- Beverage and bottled water manufacturers

- Pharmaceutical packaging producers

- Cosmetic and daily chemical bottle suppliers

- Glass and plastic container manufacturers

- Quality inspection agencies and testing laboratories

In each case, bottle verticality test results guide process optimization and acceptance decisions.