Bottle leak tester is a critical quality control instrument used to evaluate the sealing integrity of bottles and rigid or semi-rigid containers. In industries such as packaging, food and beverage, pharmaceuticals, medical devices, and daily chemicals, even microscopic leaks can lead to contamination, reduced shelf life, or regulatory non-compliance. For this reason, leak testing has become an essential part of both R&D validation and routine production inspection.

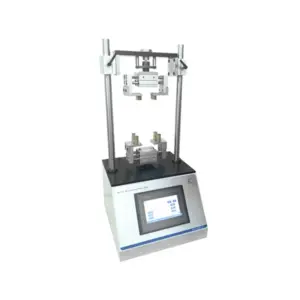

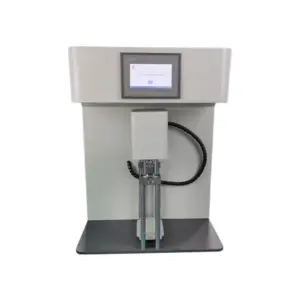

Cell Instruments Co., Ltd. designs and manufactures professional bottle leak tester systems that combine clear visual results, stable vacuum control, and flexible test configurations, helping quality professionals make confident decisions based on reliable data.

Leak Test Procedure for Bottles (Vacuum Bubble Emission Method)

The leak test procedure for bottles commonly follows a vacuum bubble emission principle, which is also referenced in ASTM D3078 – Standard Test Method for Determination of Leaks in Packages by Bubble Emission.

In this method, the bottle is placed inside a transparent chamber filled with water. A controlled vacuum is applied, creating a pressure differential between the inside and outside of the bottle. If a leak exists, trapped air escapes from the defect and appears as a continuous stream of bubbles, allowing operators to locate and confirm leakage visually.

This procedure offers high sensitivity, intuitive interpretation, and suitability for both laboratory and production environments.

Leak Test Procedure for Plastic Bottles and Plastic Containers

The leak test procedure for plastic bottles focuses on identifying defects caused by molding inconsistencies, stress cracking, or cap-seal mismatch. Plastic containers may deform slightly under vacuum, so stable and repeatable pressure control is essential.

A leakage test for plastic containers using a bottle leak tester can be configured as:

- Non-destructive testing, where deformation remains within elastic limits

- Destructive testing, where higher vacuum levels intentionally stress the container

This flexibility allows engineers to simulate real-world conditions and define safe performance limits.

Leak Test Procedure for Liquid Bottles Using an Empty Chamber

For liquid-filled packages, an alternative leak test procedure for liquid bottles uses an empty vacuum chamber without water. During testing, a vacuum is applied directly to the external environment. If leakage occurs, liquid escapes from the package and becomes immediately visible.

This method avoids dilution or contamination of the test medium and works well for beverages, pharmaceutical liquids, IV solutions, and other filled containers where bubble observation in water may not be practical.

Vacuum Leak Test for Bottles: Dye Ingress as a Verification Tool

In addition to visual bubble testing, some validation protocols require a vacuum leak test for bottles using dye ingress. The methylene blue dye method introduces a colored solution under vacuum conditions. If leaks exist, dye penetrates the package and becomes visible after opening.

Although destructive, this approach provides strong qualitative confirmation and often supports process validation or comparative studies.