Automatic torque tester is a critical quality control instrument used to measure the application torque and opening torque of threaded closures on bottles and containers. In packaging industries such as food, pharmaceutical, medical, and daily chemicals, torque consistency directly affects seal integrity, consumer usability, and regulatory compliance. Inadequate torque may cause leakage or loss of barrier performance, while excessive torque can lead to cap deformation or poor user experience.

Torque Tester for Bottle Caps & Opening Torque & ASTM D7860

Torque tester for bottle caps evaluates two key parameters: application torque and opening torque, often referred to as removal torque. These values determine how securely a closure has been applied and how much force a user must exert to open the package. ASTM D7860 provides a standardized framework for measuring torque retention of continuous thread closures using automated torque testing equipment, making it a cornerstone reference for laboratories worldwide.

ASTM D7860 defines important concepts such as dry torque, immediate removal torque, and torque retention, ensuring that results remain comparable across different materials, closure designs, and storage conditions. By following this standard, an automatic torque tester can deliver results that support package development, engineering validation, and routine quality inspection.

How the Automatic Torque Tester Works

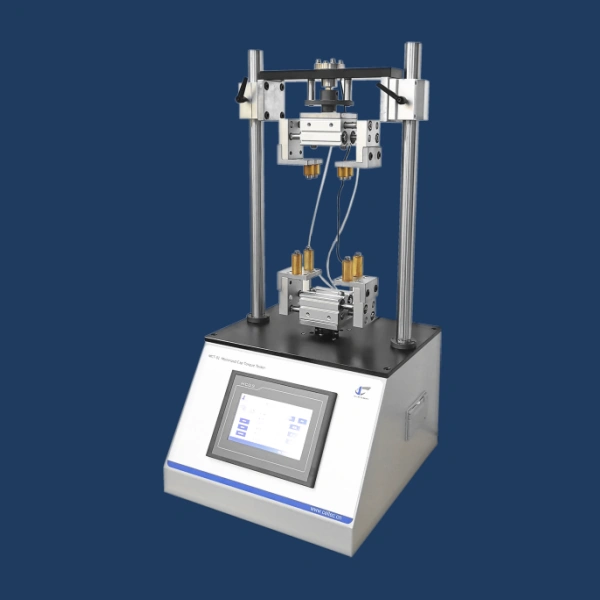

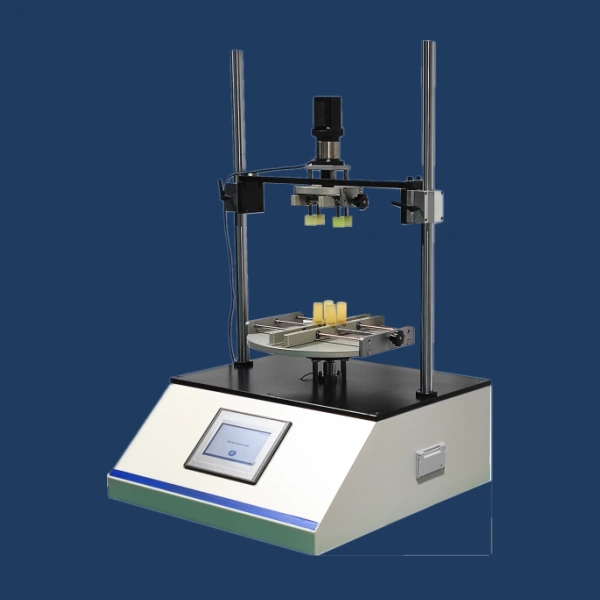

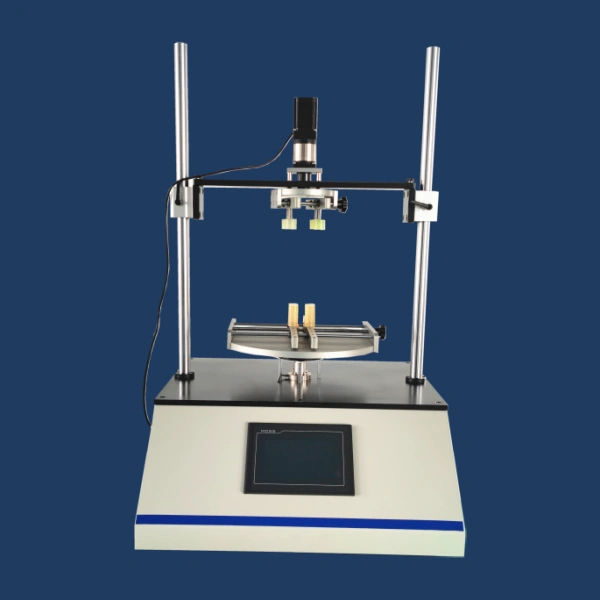

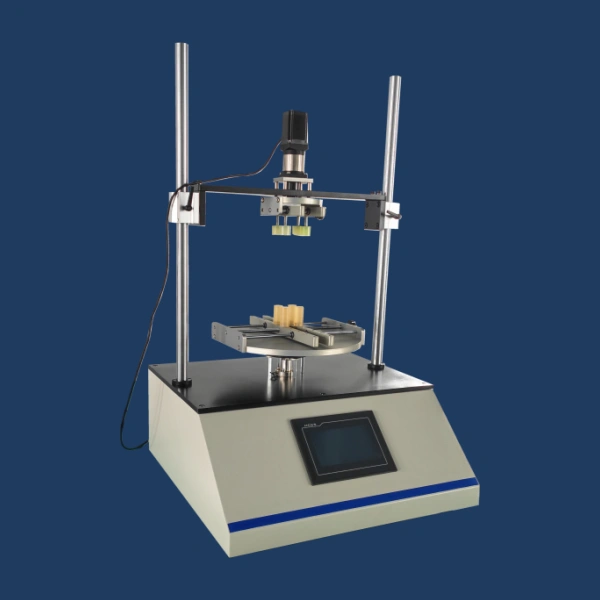

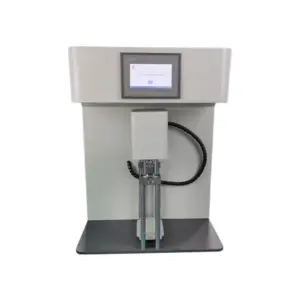

The automatic torque tester operates using a motorized rotational system combined with a precision torque transducer. The bottle and cap are secured concentrically to avoid eccentric loading, ensuring repeatable and accurate measurements.

During testing, the instrument applies a controlled rotational motion at a fixed speed or torque ramp. The torque signal is captured continuously, and the peak opening torque is automatically recorded. This approach closely reflects real-world opening conditions while minimizing operator influence.

Compared with manual devices, an automatic torque tester offers higher repeatability, reduced human error, and better alignment with ASTM D7860 requirements, especially when testing torque retention over time or after environmental conditioning.

Importance of ASTM D7860 in Automated Torque Testing

ASTM D7860 emphasizes the use of automated transducer-based torque meters operating at known rotational velocities. This requirement exists because torque behavior changes with speed and test conditions. Automated systems ensure that every sample experiences the same test parameters, which significantly improves data reliability.

The standard supports both static evaluation and dynamic evaluation, allowing manufacturers to assess torque retention after storage or simulated distribution. For child-resistant and non-child-resistant closures, ASTM D7860 helps verify that opening torque remains within a safe and functional range throughout the product lifecycle.

By aligning with ASTM D7860, an automatic torque tester strengthens audit readiness and enhances customer confidence in packaging quality systems.