Vertical Load Test for Bottle: Purpose and Practical Meaning

The vertical load test for bottle focuses on how a container behaves when a compressive force is applied along its central axis. This loading condition simulates real-world stresses such as pallet stacking, warehouse storage, and top pressure during transportation.

Key performance indicators obtained from a top load tester include:

- Maximum vertical load capacity before deformation or failure

- Yield load, where structural stiffness begins to decrease

- Deformation behavior under controlled compression

- Failure mode, such as buckling or brittle fracture

For glass containers, the test emphasizes resistance to sudden breakage. For plastic bottles, the test reveals ductility, stiffness, and design robustness.

Top Load Test for Bottles According to ASTM D2659

The top load test for bottles made from thermoplastics follows the principles defined in ASTM D2659, which addresses column crush properties of blown plastic containers.

ASTM D2659 specifies testing under a constant compressive deflection rate, ensuring that results remain comparable across laboratories. The method focuses on:

- Crushing yield load

- Deflection at yield

- Crushing load at failure

- Apparent crushing stiffness

A compliant top load tester must maintain a stable and controllable test speed, typically between 12.5 mm/min and 50 mm/min. Proper specimen alignment and venting play a decisive role in test accuracy and safety.

By following ASTM D2659, packaging engineers can use top load data for quality control, acceptance testing, and R&D comparisons, especially when evaluating design changes or material substitutions.

Bottle Vertical Load Testing Based on ISO 8113

For glass packaging, ISO 8113 defines the standardized method to measure resistance to vertical load. This international standard ensures consistency when evaluating bottles used in beverages, food, and pharmaceuticals.

ISO 8113 emphasizes:

- Temperature equilibrium between sample and environment

- Accurate axial alignment of the container

- Use of protective pads or closures to simulate real sealing conditions

- Controlled force application until a specified load or breakage

A professional top load tester designed for ISO 8113 supports both pass tests (loading to a predefined value) and progressive tests (loading until failure). These results help manufacturers confirm that glass containers meet internal specifications and customer requirements.

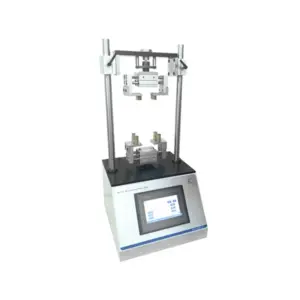

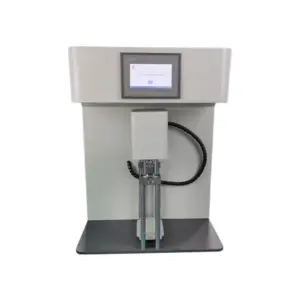

How Top Load Tester Work

A top load tester applies a controlled vertical compressive force through precision platens while continuously measuring force and displacement. The system records real-time load–displacement curves, allowing users to observe structural response throughout the test.

Modern systems from Cell Instruments integrate:

- High-accuracy load cells

- Precision displacement measurement

- PLC-based control with intuitive HMI

- Digital data output for traceability

This configuration ensures that every top load test for bottles remains repeatable, traceable, and compliant with ASTM and ISO standards.

Why Top Load Testing Builds Confidence and Trust

Reliable vertical load data supports better decisions across the packaging lifecycle. A validated top load tester helps:

- Prevent container collapse during logistics

- Reduce material usage without compromising safety

- Demonstrate compliance during audits and customer evaluations

- Improve consistency across production batches

By aligning testing practices with ASTM D2659 and ISO 8113, manufacturers strengthen both technical credibility and customer trust.